Standard Zry is sufficiently exhausting to be prone to stress-corrosion cracking (SCC) when the pellet–cladding gap closes and the swelling gas generates substantial tensile hoop stresses in the cladding. In the presence of an aggressive fission product (iodine is most frequently cited), a brittle crack can be initiated and penetrate the cladding wall. This is a main cladding failure that admits steam into the rod with the accompanying potential for a more serious secondary failure due to hydriding. The mixture of conditions (vulnerable metal, tensile stress, and chemical enhancer) that produces the first defect is termed pellet–cladding interplay (PCI). The original purpose of tin in Zry was to mitigate the loss of corrosion resistance attributable to pickup of impurity nitrogen during fabrication of the alloy.

Most of the metallic cladding for the building business is pre-painted in coil previous to the manufacturing of the cladding panels. Metal cladding is used for both protection from environmental components and aesthetics of the building. The paint utilized by coil coating gives the metallic extra durability, corrosion resistance and final look. Arconic argued that the tragedy at Grenfell was not the result of its panels, but the combination of supplies used within the 2016 £10m refurbishment, singling out the plastic window frames by way of which the fire was believed to have first unfold from flat 16 into the cladding system.

After melting and bonding by the laser, the alloy layer was 1.5 mm thick and had very little dilution from the steel. The resulting floor had glorious put on resistance. Architectural metallic cladding is the collective term for exterior constructing cladding made from coated metallic. In the last many years metallic grew to become one of the well-liked constructing materials for the building envelope amongst architects and builders.

Phase transformation of Zirconia is, nevertheless, of great concern. Zircaloys additionally endure from bad creep rates. In contrast to floor-layer welding, explosive welding causes no change in microstructure, and corrosion resistance of the layers isn't affected (Pocalco 1987 ). ions from the surroundings to the response entrance on the metallic/oxide boundary.

The government’s building safety programme has targeted primarily on instant interim mitigation actions and permanent replacement of unsafe aluminium composite material (ACM) panels on high-rise buildings because of the acute risks posed by such panels.

The interplay that gasoline cladding tubes expertise as a result of fission products on the inner floor is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are a number of the fission merchandise which contribute strongly to the SCC course of.

laser beam. The alloy was overlaid on the metal as a powder layer 2.5 mm thick.

Moore-Bick has confronted widespread calls to conclude in his interim report – expected next spring – that the £10m refurbishment, using extremely combustible cladding panels, was in breach of constructing rules. But he has also heard conflicting proof about whether the fireplace brigade should have tried to order a full evacuation before the constructing was engulfed in flames trapping and killing households and associates who huddled collectively in flats. Earlier in Wednesday’s hearing firefighters blamed the Royal Borough of Kensington and Chelsea for failing to make an evacuation plan for Grenfell Tower, regardless of skilled advice taken before the catastrophe and legal obligations making clear it was essential. The efficiency of the uPVC home windows within the fourth floor flat where the fire began, the artificial insulation and other decorative cladding panels throughout the rest of the constructing had been successfully answerable for spreading the fireplace, he stated.

In order to prevent or decrease pellet/clad interactions, each mechanical and chemical, a coating of graphite powder is applied on the inner surface of cladding tubes. The graphite layer supplies lubrication to reduce the mechanical interactions, and acts as a barrier towards the migration of harmful species to stressed areas of fuel tubes. Laser cladding often includes covering a comparatively inexpensive substrate materials with a costlier alloy that can increase the resistance of the part to wear or corrosion. Cladding allows the bulk of the half to be made with inexpensive material, while providing the surface with desirable properties associated with the more expensive cladding material.

The impact of loss of metal by inner or outer corrosion is much less important for thick cladding than for thin-walled tubing. For the same external loading, the stress produced within the cladding, both exterior from the coolant or inside from fission-product swelling of the gasoline, is decreased in proportion to the wall thickness. However, thick cladding is detrimental to neutron economic system, increases the amount of the reactor core, raises fuel temperature, and prices more than skinny-walled tubing. The compromise between these competing demands has produced wall thicknesses of ∼0.9mm in BWRs and ∼0.7mm in PWRs. is produced and the chance of an enormous secondary hydriding failure is elevated.

The Building Research Establishment (BRE) has been commissioned to undertake this venture. This programme is on-going and tests are expected to conclude in the summer.

The blades had a machined pocket, into which powdered cobalt-based metal (Stellite 6) was fed ahead of the laser beam. The resulting cladding layer was well bonded, and the blades exhibited improved fatigue characteristics in contrast with blades fashioned by the standard silver brazing process.

It comes almost two years after 72 folks died within the Grenfell Tower fireplace. Fire security experts warn lots of the 1,700 buildings identified as "in danger" in England are more likely to fail new exams into cladding and constructing materials. , the place T is the absolute temperature and β is the burnup. The constants a and b are primary properties of the material and may be decided from standard laboratory experiments on fresh fuel. The thickness of the cladding might range between zero.1 and 30 mm and the detonation velocity is between 1200 and 7000 ms −1 .

â–¾Dictionary English-German

laser beam. The alloy was overlaid on the steel as a powder layer 2.5 mm thick.

Standard Zry is sufficiently exhausting to be susceptible to stress-corrosion cracking (SCC) when the pellet–cladding hole closes and the swelling fuel generates substantial tensile hoop stresses in the cladding. In the presence of an aggressive fission product (iodine is most frequently cited), a brittle crack may be initiated and penetrate the cladding wall. This is a primary cladding failure that admits steam into the rod with the accompanying potential for a extra critical secondary failure because of hydriding. The mixture of circumstances (vulnerable metal, tensile stress, and chemical enhancer) that produces the first defect is termed pellet–cladding interaction (PCI). The unique purpose of tin in Zry was to mitigate the lack of corrosion resistance caused by pickup of impurity nitrogen during fabrication of the alloy.

These frameworks have been utilized and peer reviewed inside the scope of fireside research research on the fireplace efficiency of aluminium composite panels and insulation supplies at The University of Queensland and the University of Edinburgh. This large scale check, undertaken by the Fire Protection Association (FPA), examined a HPL panel system with stone wool insulation, in accordance with British Standard 8414. This check involves constructing a 9-metre excessive wall with a complete cladding system fastened to it - including panels and insulation. This was then subjected to a hearth designed to replicate the circumstances during which a extreme hearth breaks out of a window.

The BWR coolant usually contains a higher stage of oxygen, sometimes 200–400 ppb. Hydrogen addition in boiling water situations just isn't very effective due to the segregation of hydrogen within the steam phase. The government has arrange a fund to remove cladding from buildings recognized with aluminium composite materials (ACM) - the identical type used on Grenfell Tower. The new tests, which started final month, are testing different types of cladding and building materials.

With the development of an equilibrium pore and crack structure within the oxide layer, the oxidation price successfully becomes linear, a attribute feature of the publish-transition oxidation conduct. Alloying components, notably tin, niobium, and iron, present in the α-strong solution strongly affect both the kinetics and the mechanism of oxide development in zirconium alloys. The thickness of the cladding is a design parameter dictated by conflicting efficiency requirements.

The joint is then caused by a deformation-induced melting bathtub. The soften layer is sort of skinny; for example, when cladding an aluminum alloy it's about 0.5–fourμm (Kreye 1985, 1997 ). The dilution of the molten zones results in airplane or corrugated interfaces.

It comes virtually two years after 72 people died in the Grenfell Tower fire. Fire safety experts warn lots of the 1,seven-hundred buildings identified as "at risk" in England are more likely to fail new tests into cladding and building supplies. , the place T is absolutely the temperature and β is the burnup. The constants a and b are fundamental properties of the fabric and can be decided from normal laboratory experiments on recent fuel. The thickness of the cladding might range between 0.1 and 30 mm and the detonation velocity is between 1200 and 7000 ms −1 .

The spread of the fire up the surface wall, if any, was then monitored. The Independent Expert Advisory Panel also advised the division to determine a research challenge to test and improve the evidence obtainable on the behaviour of a variety of non-ACM supplies used in cladding methods when subjected to fire.

Zircaloys have anisotropic bodily, mechanical, and chemical properties. Within the oxide layer, the alloying components affect the atomic transport such that the alloying concentration determines the corrosive conduct, with high alloying concentrations (above ∼0.6%) providing safety in opposition to oxide progress. Today, Zircaloy-2 and Zircaloy-4 are broadly used.

The Building Research Establishment (BRE) has been commissioned to undertake this project. This programme is on-going and exams are anticipated to conclude in the summer.

The prime plate hits the underside plate with a velocity of one hundred–one thousand ms −1 , and pressures are in the range of 10 to one hundred kbar. Under certain circumstances a superheated layer of material types within the contact space.

Metal is the most power-efficient and sustainable building materials obtainable. Next to this it is almost utterly recyclable and present metal coils include a excessive recycling content up to ninety five%. The engineering of our materials additionally makes our cladding a strong resilient form of exterior overlaying . The bonding agent reinforces the picket components, and our components improve the cladding’s weather resistance.

Due to the combined effects of thermal enlargement of gasoline pellets, fuel swelling due to fission gasoline release, and the coolant stress on the outer surface of gas tubes, cladding tubes collapse on the gas pellets. In PWRs the closure of the gap between the pellet and the clad takes about one full energy 12 months while the hole is maintained for a longer interval in BWRs.

Cladding is an outer layer of either vertical or horizontal material, used to improve the appearance, thermal insulation and the weather resistance of a constructing. Our cladding is on the market in quite a lot of sizes, kinds of timber and surface finishes. Enhance the curb attraction of your home with B&Q cladding. All of our timber is responsibly sourced forest friendly timber. Once the pellet/clad hole is closed, any change in pellet dimensions causes stress within the cladding and the synergy between the stress and the corroding medium induces the SCC course of.

About Our Cladding Products

The BWR coolant often incorporates the next stage of oxygen, sometimes 200–four hundred ppb. Hydrogen addition in boiling water circumstances is not very effective due to the segregation of hydrogen within the steam section. The government has set up a fund to take away cladding from buildings identified with aluminium composite materials (ACM) - the identical sort used on Grenfell Tower. The new checks, which began final month, are testing other kinds of cladding and building materials.

The interaction that gas cladding tubes experience as a result of fission merchandise on the inner surface is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are some of the fission products which contribute strongly to the SCC course of.

Modified low-tin alloys can be utilized either as an entire substitute for the Zry tube wall or as a skinny outer pores and skin on commonplace Zry substrate tubing. 1.5% tin, and the balance being iron, nickel, and chromium. Its industrial title is Zircaloy, or Zry for short.

The effect of lack of metal by inside or outer corrosion is much less important for thick cladding than for thin-walled tubing. For the identical exterior loading, the stress produced within the cladding, both external from the coolant or internal from fission-product swelling of the gas, is lowered in proportion to the wall thickness. However, thick cladding is detrimental to neutron financial system, increases the volume of the reactor core, raises fuel temperature, and costs greater than thin-walled tubing. The compromise between these competing demands has produced wall thicknesses of ∼zero.9mm in BWRs and ∼zero.7mm in PWRs. is produced and the danger of an enormous secondary hydriding failure is elevated.

The spread of the fire up the outside wall, if any, was then monitored. The Independent Expert Advisory Panel also suggested the division to establish a analysis venture to check and improve the proof obtainable on the behaviour of a spread of non-ACM supplies used in cladding systems when subjected to fireside.

The prime plate hits the underside plate with a velocity of a hundred–1000 ms −1 , and pressures are within the range of 10 to one hundred kbar. Under sure conditions a superheated layer of material forms in the contact space.

Differential swelling between cladding, wrapper tube, and spacing system (spacer wire or grids) can induce additional stresses and deformations on these parts and/or generate coolant circulate perturbations in the bundle. These phenomena have been studied and have significantly shown that wires or grid materials should be chosen and specified so as to reduce differential swelling. Laser cladding has been applied to hardening of steam generator turbine blades and reached pilot manufacturing standing [four ].

Cladding look at here now Modes

The joint is then attributable to a deformation-induced melting bathtub. The melt layer is sort of skinny; for example, when cladding an aluminum alloy it's about 0.5–4μm (Kreye 1985, 1997 ). The dilution of the molten zones results in plane or corrugated interfaces.

Cladding is an outer layer of either vertical or horizontal material, used to enhance the looks, thermal insulation and the weather resistance of a constructing. Our cladding is out there in a variety of sizes, forms of timber and surface finishes. Enhance the curb appeal of your home with B&Q cladding. All of our timber is responsibly sourced forest pleasant timber. Once the pellet/clad gap is closed, any change in pellet dimensions causes stress in the cladding and the synergy between the stress and the corroding medium induces the SCC course of.

In December, the government launched new fire safety rules in response to Dame Judith Hackitt's impartial review following the Grenfell Tower fireplace. A public inquiry into the fireplace, which occurred in west London in June 2017, heard evidence to help the speculation that the extremely flamable materials in the cladding was the primary reason for the fireplace's spread.

During mechanical decladding, the gas assemblies are chopped and the fuel core is leached with nitric acid, abandoning the undissolved cladding materials for disposal as a stable waste. This methodology is adopted for zircaloy-clad fuels from energy reactors and stainless-steel-clad quick reactor fuels. Cladding gear is generally designed to suit a specific product or a gaggle of products; this significantly applies to the items required for uncoiling of the strip and the feeding device. The materials and surface of the rolls as well as their geometrical shape (cylindrical or topped) are crucial. Depending on the materials to be bonded, cleaning and roughening are finest accomplished by brushing, grinding, or scraping using a specifically designed cutter with needles.

The oxidation course of and the character of the oxide layer on a zirconium alloy pattern are schematically illustrated in Fig. 6 .

Zry manufacturing methods now supply much better control of gaseous impurities than early fabrication technology, so the unique cause for adding tin is moot. Since tin is a substitutional impurity, its function is to increase the power of Zry over that of pure zirconium.

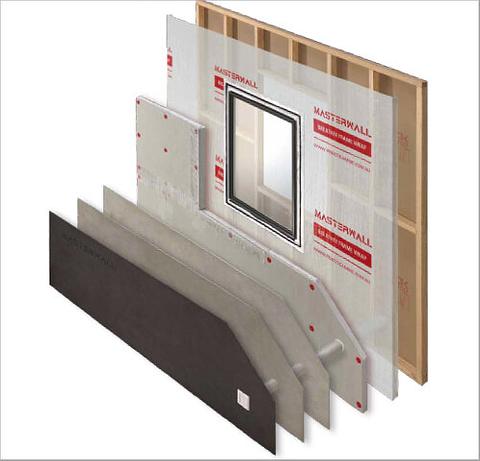

A suction removing unit is used to evacuate rigorously any materials waste so as to avoid bonding flaws as a result of poor adhesion. Hanover House, a residential tower block in Sheffield, with its cladding partially removed after failing fire safety tests following the Grenfell Tower fireplace. Cladding in construction is material applied over another to supply a pores and skin or layer and used to provide a level of thermal insulation and weather resistance, and to enhance the looks of buildings. Between the cladding and the wall there's a cavity the place rain can run down. an industrial primer of wood for facade cladding and prefabricated parts for picket houses.

After melting and bonding by the laser, the alloy layer was 1.5 mm thick and had very little dilution from the metal. The ensuing surface had glorious put on resistance. Architectural metal cladding is the collective time period for exterior constructing cladding produced from coated metallic. In the final a long time metallic became one of the most in style constructing materials for the constructing envelope amongst architects and builders.

Zry comes in two varieties, Zry-2 and Zry-four. These two differ by minor adjustments in the concentrations of the transition metals (Zry-four has no nickel). PWRs use Zry-4 while BWRs make use of Zry-2 as cladding and either Zry-2 or Zry-four for the duct or channel holding the fuel-component bundle. The transition metals iron and chromium seem within the microstructure as precipitates of the intermetallic compounds Zr 2 (Ni,Fe) and Zr(Cr,Fe) 2 . These minor alloying elements improve corrosion resistance to an extent dependent on the dimensions of the precipitates.

Metal is essentially the most vitality-efficient and sustainable constructing supplies obtainable. Next to this it's almost utterly recyclable and current steel coils contain a high recycling content as much as ninety five%. The engineering of our supplies additionally makes our cladding a robust resilient form of exterior covering . The bonding agent reinforces the wooden elements, and our components improve the cladding’s weather resistance.

tube. Energy, from fission, is generated roughly uniformly throughout the fuel pellets. Heat is extracted on the rod floor by the coolant flow. The temperature at the hottest level, at the pellet centerline, is often in the range 800–one thousand °C, depending on the power level. The metallic cladding is a good conductor, so the temperature rise across the wall is just a few tens of degrees.